MCI Precision (Cambridge) was established in 1982, in partnership with a French company. The company has since come under new management in 2009, but have retained the excellent level of customer service and quality of production that we have always been known for. Within the UK, we are the holders of several prestigious supplier awards and the recognised first choice for hybrid screens.

MCI Precision have continued to develop their high precision printing screen technology to support innovation towards ever smaller, precise and reliable products. We have now worked alongside companies within a variety of different industries, including automotive and ground transportation electronics, aviation, space, medical, defence, smart cards and Photovoltaics.

We are fully registered in the UK to BS EN ISO9001: 2015. Our Quality management system is constantly being updated to improve the service we offer our customers.

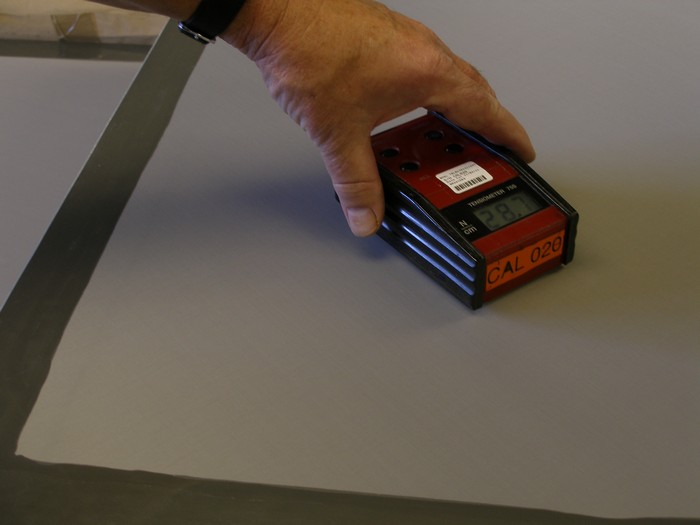

Tension Gauge

The TETKOmat is a portable compact mechanical tension measuring device for accurate and consistent measurement of a screening media.

It has a simple, quick direct reading measuring systems with equivalent values for Newtons per centimetre (N/cm), printed on its base.

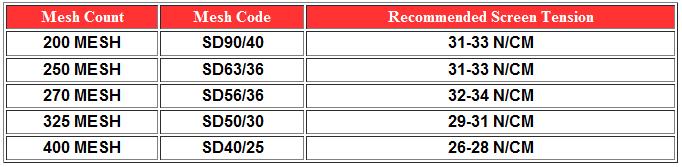

Screen tensions are expressed in N/cm, which relates the amount of force required to provide a fixed deflection. Uniformity of tension will help ensure uniformity in precision printing applications.

The TETKOmat measurement readings are easily related to the recommended N/cm figures. The high sensitivity of the TETKOmat allows measurement of tension variations within a screen regardless of frame size. This enables the screen to make to correct or change tensioning techniques to achieve the most uniformly tensioned screen.

Correct and uniform screen tension optimises screen life and stability.

The TETKOmat offers the following advantages:

- Substantial improvement in tension measurement over the time honoured methods such as touch control, gauging by the percentage of fabric elongation, and psi pressure values of deflection

- Accurate measurements to check used/reclaimed screens to eliminate worn-out units from production.

- Tension measurements are independent of screen size.

- Warp and weft directions can be checked separately.

- Reproduce and uniform tension, screen after screen.

- An affordable production tool for all sizes of operations.

- Small compact gauge ideal for high volume screen users where more than one TETKOmat is required.

- Improves print registration and reduces rejects resulting in increased productivity.